Unidirectional, Spread Tow Carbon: A Revolutionary Innovation in the World of Marketing

Unidirectional, spread tow carbon is a remarkable innovation the global world of marketing just like the anjie Carbon fiber pre preg sheet. This has the potential to provide a number of advantages over traditional materials and offers improved safety, quality, and performance. We will discuss whis, the advantages of using it, and exactly how it could be utilized.

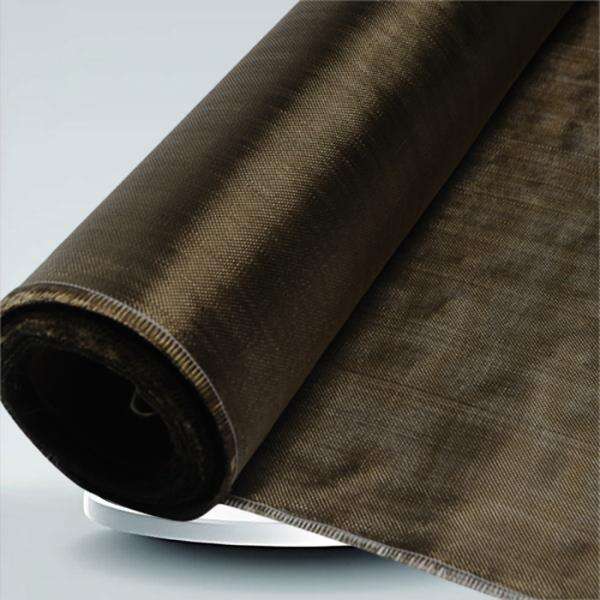

Unidirectional spread tow carbon of anjie is a fabric made of carbon woven fibers in a specific pattern causing a material with exceptional strength and stiffness. This has an unidirectional pattern, meaning that the carbon fibers are arranged in a single direction ensuring that their strength is maximized in that direction. The fabric further benefits from not only being unidirectional but also from the spread tow pattern in which the fibers are arranged. The fibers are placed by this arrangement close together, making sure the fabric has minimal gaps. The effect is a stronger fabric and stiffer than traditional materials.

Unidirectional spread tow carbon possesses true number of same with anjie twill carbon fiber cloth roll. The 1st is its strength. Because of its unique fiber arrangement it is significantly more powerful than traditional materials such as aluminum and steel. This energy also helps it be incredibly stiff, making it well suited for applications where high degrees of stiffness are essential. An additional benefit of unidirectional, spread tow carbon is its fat. It is incredibly lightweight, which makes it perfect for usage in applications where weight reduction is critical, like the aerospace and industries that can be automotive. A spread tow carbon bonus additional its corrosion resistance. Unlike traditional materials, it is really not susceptible to corrosion and will keep going longer than many other materials.

Unidirectional spread tow carbon from anjie is not only stronger than traditional materials, however it could be safer. Due to its stiffness, it may better resist impact and reduce the likelihood of injury or harm. Furthermore, due to its corrosion-resistant properties, it doesn't pose the identical safety to traditional materials. When using unidirectional, spread tow carbon, it is vital to check out proper security and managing protocols. The material is highly potent and needs specific training knowledge handle it properly.

Unidirectional spread tow carbon can be utilized in a variety of applications, including automotive, aerospace, and sporting good same with anjie Carbon fiber pre preg fabric. The materials can be formed in various size and shapes and that can be molded into complex shapes that may be impossible with otherwise traditional materials. The entire process of using unidirectional, spread tow carbon depends within the application and will range from hand layup to automated processes as automated tape filament and laying winding.

customers will satisfied with product service. will create ongoing business relationship. With more 20 years dominance composite materials supply, ANJIE certified ISO9001:2015 Quality, ISO14001 :2015 Environmental, ISO 45001:2018 Safety Safety, unidirectional, spread tow carbon factory evaluation report, CE mark awarded numerous other certificates. products made according international standards meet ASTM specifications. Reviews customers about products thoroughly evaluated any issues occur before after goods arrive client's premises resolved immediately. clients ANJIE around globe enjoyed wide range technical assistance. includes dedicated team, product samples, solving issues using highest quality, and continuous customer service.

Research development modern technology make most composite materials explore new avenues applications products regular daily activities ANJIE. Modern construction various fields always need updated technologies products. ANJIE RD team continuously unidirectional, spread tow carbon new products innovation provide cost efficient solutions efficient application such materials. offers new products often able meet customers' diversified application needs. addition, technical experts assist solve problems encountered during after projects products built site. Online consultation, material support visit site, testing arrangements etc. ANJIE assures all required tests conducted.

company among largest composite material producers exporters, specializing mainly carbon fibers, aramid fibers fiberglass materials. regularly exports international market. It more unidirectional, spread tow carbon patented high-tech machines active production line. company equipped dedicated QC team expert laboratory tests products prior each shipment. advanced technologies company ensure that it able supply high-quality products consistently effectively. It various national reward certifications products, such ISO, SGS, CE more. If are search an established dependable supplier products, lasting customer service, ANJIE reliable partner.

manufactures variety fiber products specifically widely employed unidirectional, spread tow carbon, construction, automotive, Sports, Wind energy fiber composite-based construction. Since 2004 ANJIE has manufacturing carbon fiber-based products such carbon fiber fabric ud carbon fiber plates geo grids, fiber rebar rod chop fiber, so on. Such materials used construction structural strengthening structural strengthening. It good reputation manufacture 3k carbon fiber, carbon aramid glass hybrid fabric carbon fiber prepreg, biaxial fiber fabric, silica glass fiber fabric numerous others. materials utilized aviation, sports boat, as well many automotive parts manufacturing model. They resin factories meet needs clients requirements. carbon fiber aramid further, ANJIE comprehensive range composite materials suited variety applications across various industries, including aerospace, automotive, marine construction, marine, much more.

Unidirectional spread tow carbon made by anjie is truly a premium material that requires specialized expertise knowledge to produce. It is really important to ensure that the material you might be using is of good quality also it meets your specific requirements. When selecting a supplier for your unidirectional, spread tow carbon needs, it is essential to choose a provider with expertise and expertise in the market. The provider should always be willing to work utilising the best quality product with you to definitely meet with the specific needs and supply you.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved